Innovative Balcony Stub Design

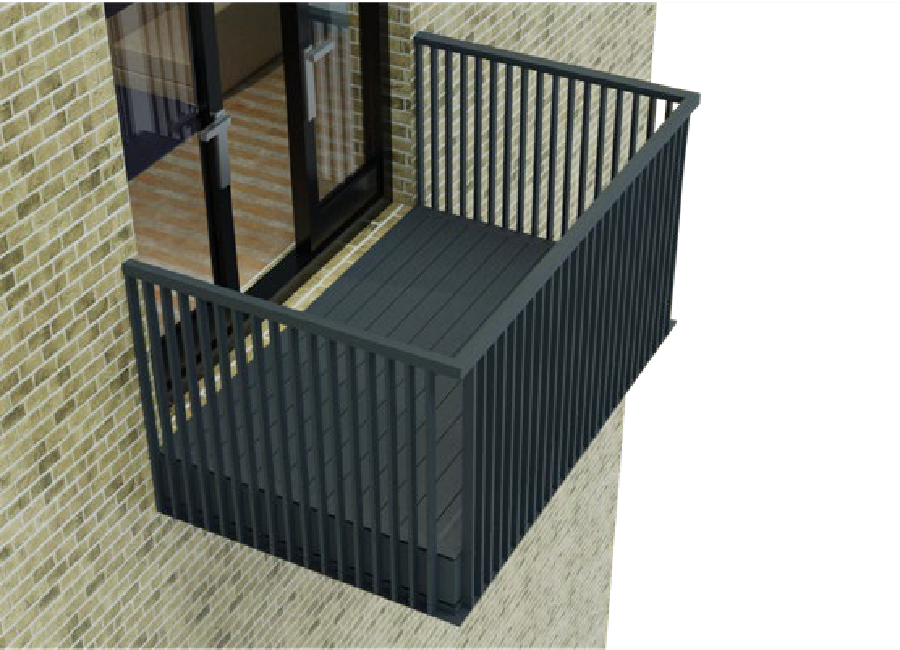

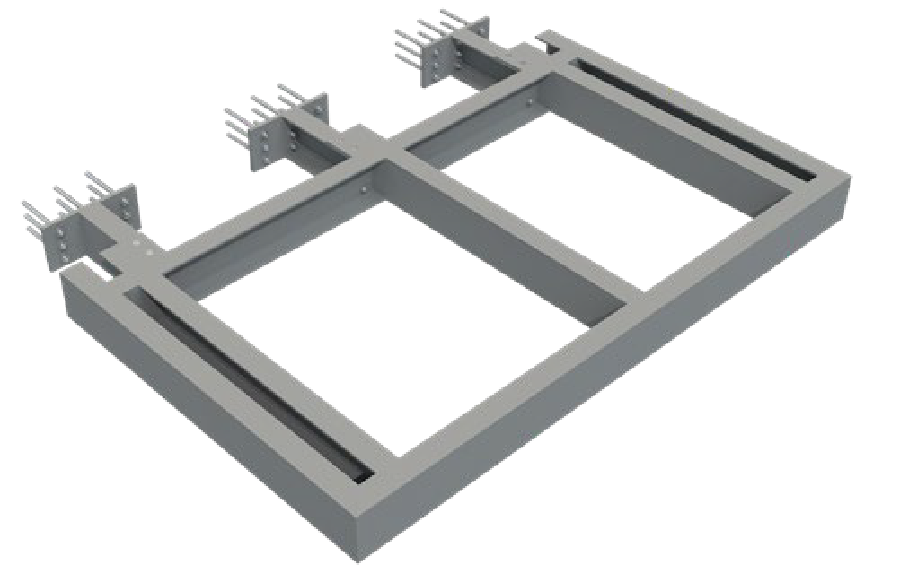

The Deep Balcony fixing system

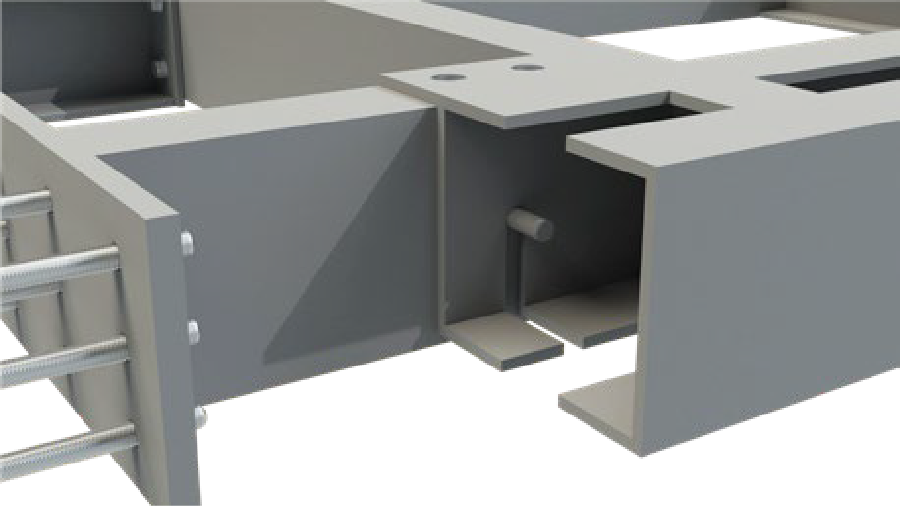

From the origins of a traditional cast in RC detail, Deep have developed an integrated protruding thermally broken stub system designed to support a fully assembled balcony from the temporary to permanent installation phase.

Bespoke stub projection dimensions are coordinated and designed specifically to suit the project cavity size. Our stubs are supplied free issue to our client for casting into RC details and formwork.

A sacrificial template accompanies stub assembly units per balcony ensuring ease of setting out, line & levelling for within tolerance pre-assembled balcony unit installation when site is ready.

The coordinated design between balcony stub and unit carcass ensuring safe and seamless installation.

Our Solution

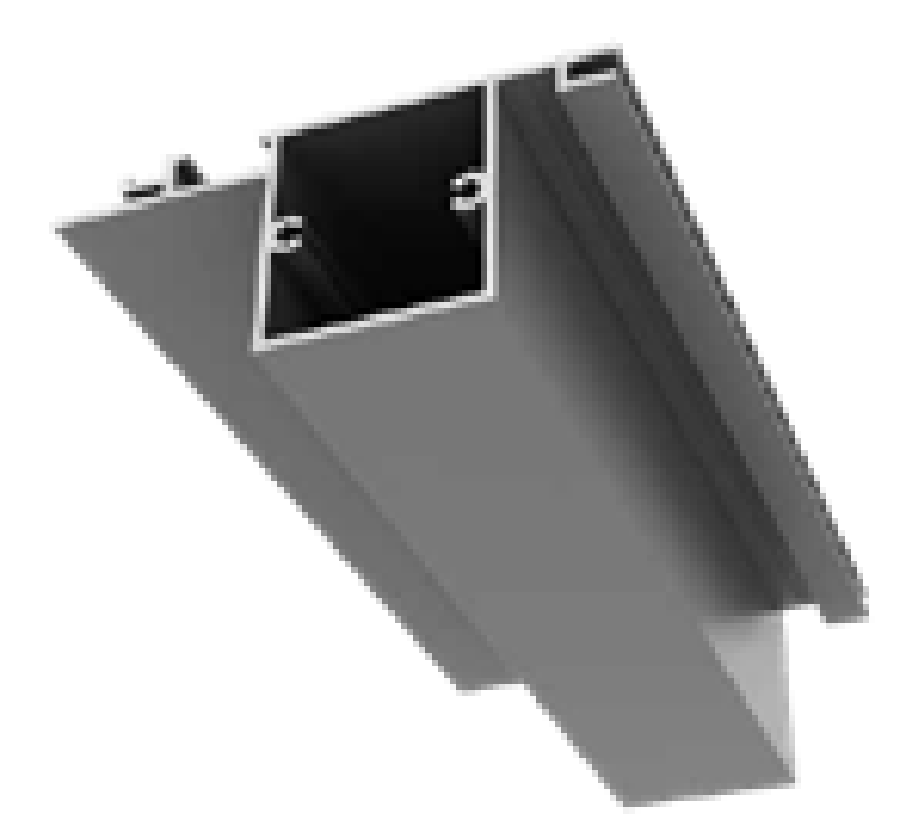

By incorporating an innovative patented pending stub system, together with the cohesive design of non-combustible aluminium component parts – the Deep balcony positions itself as the UK’s market leader in respect of quality, material traceability, engineering and safety of delivery and installation.

Advantages of Our System

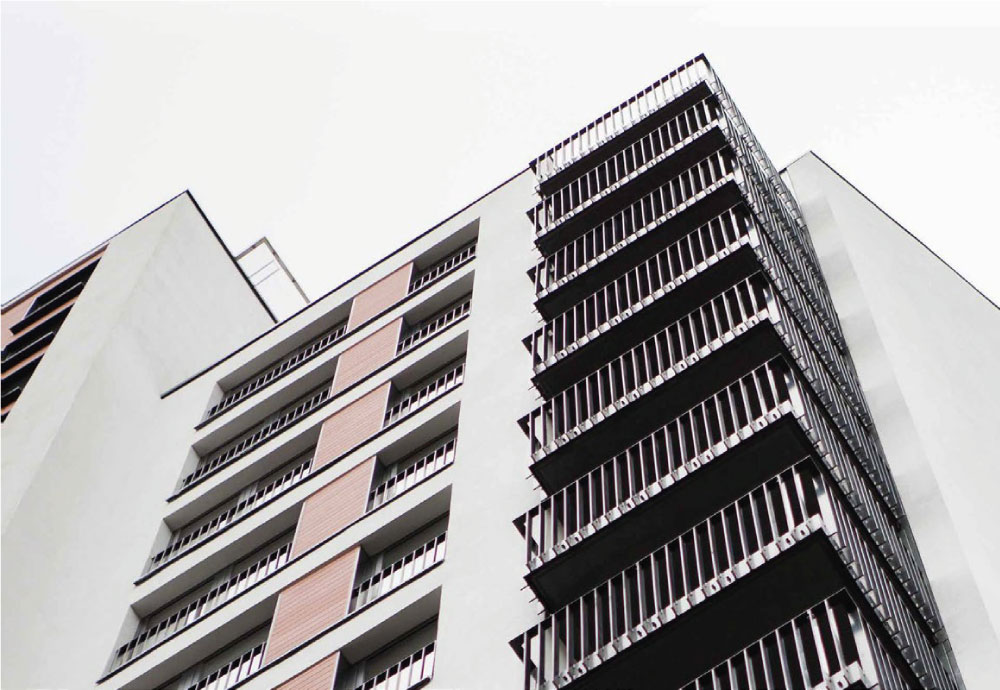

As a result of trusted trading partnerships with our supply chain and their own extensive product ranges means the Deep Balcony can incorporate your project’s unique brand identity while maintaining consistency in quality and output capacity from our manufacturing facility.

Flexibility of our Product Range

Our design has unrivalled flexibility to match specific project requirements including a large range of RAL colours, incorporating lighting features or porcelain floor finish options.

Bespoke Project Design

Utilising our in-house design and engineering service all deliverables are detailed and coordinated with the project’s professional team to approval.

Manufacturing Capacity

Manufacturing from a 40,000sq/ft state of the art fabrication facility in the UK we can supply over 2,500 Deep Balconies nationwide.

Our Product

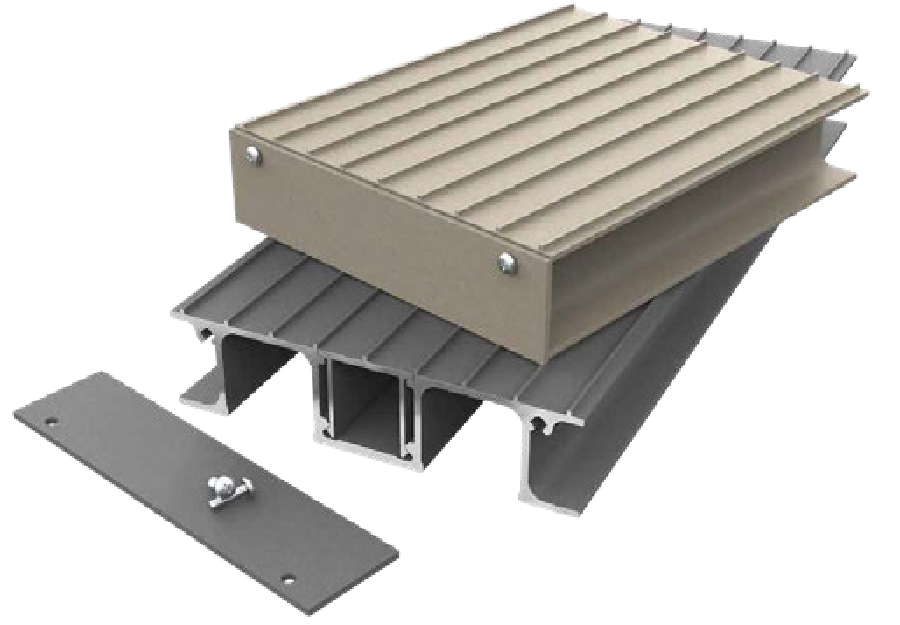

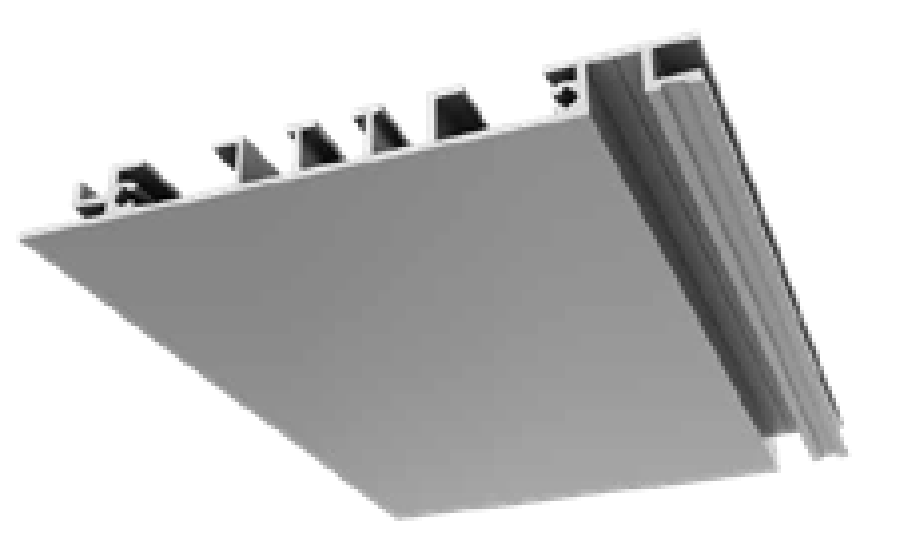

The Deep Balcony is a representation of the seamless combination of Mild Steel Galvanised carcass and Aluminium balustrade and A1 compliant decking and soffit system that incorporates water management solutions. Aluminium is a strong and durable material, able to withstand decades of use with minimal maintenance. A key property of aluminium is that it does not rust, even when exposed to wet environments over many years.

Aluminium decking with a powder-coat finish provides a near-zero maintenance solution for use in balconies, with just simple cleaning required. Highly resistant to damage due to its inherent strength, the aesthetic properties, slip resistance and durability of powder-coated aluminium decking can be expected to last for decades.

Our Aluminium Balustrade system is designed and manufactured with newly incorporated building regulation compliant inclined top rail.

Materials

Mild Steel

Marrying the rigidity of a fully fabricated mild steel carcass with architectural aluminium components parts provides our balconies with the solidity to limit deflection and provide end users with the confidence of our quality and workmanship.

Aluminium

Much of our focus during the design development phase had been to minimise gross weight of our balcony assemblies while maintaining strength and loading capacity.

The result is our product’s use of extruded aluminium decking, balustrade and water management soffits becomes beneficial to our clients – the Deep Balcony is designed to reduce deflection, quantities of stubs in turn a reduction in compromising slab penetrations and thermal and minimise carbon footprint.

Galvanising

After fabrication and quality assurance certification, all balcony carcasses are hot dip galvanised to provide corrosion resistance as necessary in an external environment.

Qualicoat

External aluminium components are finished in a controlled environment in Qualicoat Class 3 Paint to a wide range of RAL colours. Aluminium decking, soffits and balustrades are all finished by the same process and to the same high specification providing a uniquely uniform aesthetic.

Water Management Systems

Our balconies can be supplied with or without soffit cladding subject to project requirements. Incorporation of fully non-combustible soffit system can include:

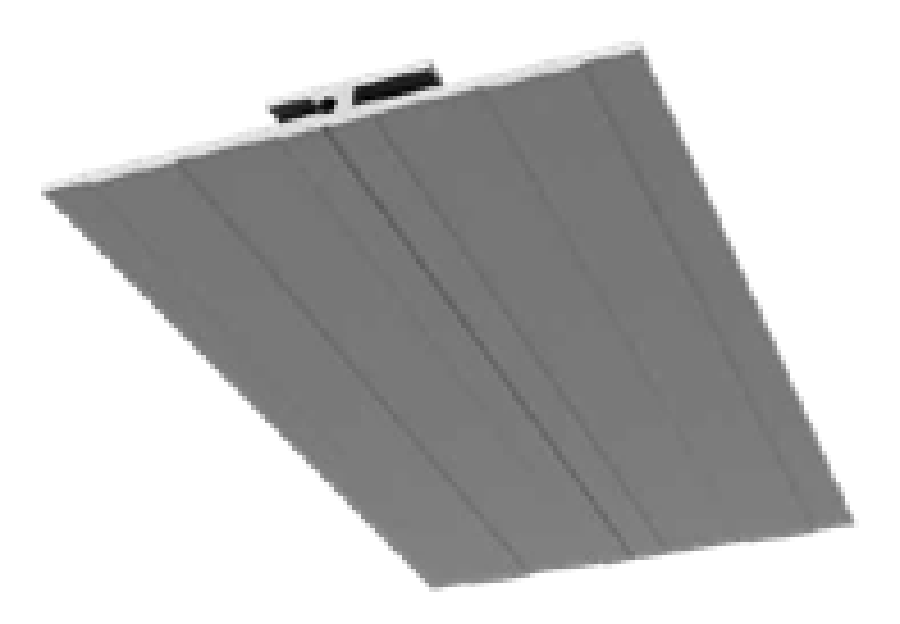

Lite

Free-draining options via the Lite system, this product is simple and is ideal for low rise construction.

Flow

Free draining through 5mm gaps between deck boards, water drains into an internally grooved set to fall front perforated channel and away from the building facade.

Decor

A decorative positively drained system with decking perimeter channel – often flowing into a cavity or external building drainage system.

Quality Assurance

Each Deep balcony is supplied with the following full certification:

CE Execution 2 certification

Our balconies are supplied with Declarations of Performance to certify their manufacture in accordance with CE Execution Class 2.

Non combustible

Independently tested to EN 13823, EN 13501 and EN ISO 1716, the Deep Balcony System achieves Fire Ratings of A1 and A2fl-s1, exceeding legislation and ensuring compliance for new build and renewal projects. Additionally, the decking boards have undergone Slip Resistance testing and all boards have been certified as “Low Risk” for slips in wet and dry conditions.

Quality Assurance Record

Deep Balconies Quality Assurance is recorded via FieldView from material traceability, manufacturing, installation and handover.

Browse the brochure